It’s easy to get lost in the multitude of pipe stands out there.

Given the hundreds of available options in the market, you might mistakenly buy pipe stands for welding, when you actually need a stand for cutting.

Then there’s the complexity of how various factors affect pipe characteristics and compatibility with stands.

To save time, minimise cost, and maximise worksite productivity, read this article to learn how to choose and buy the appropriate stand for installing, repairing, or fabricating pipes.

Choosing the Ideal Pipe Stand: Factors and Tips

Your simple table or trusty pipe holder may have carried you through dozens of projects.

But the truth is, your old reliable tool may just be plain lucky. In pipe fitting and fabrication, you cannot leave anything to chance. Choosing the appropriate pipe stand is essential for ensuring efficiency, safety, and accuracy in your workplace.

We discuss below the main factors to think about when choosing a pipe stand for your next project. Each factor discussed is accompanied by one or more tips for selecting the appropriate pipe stand.

The table below provides a summary of the key points that will be discussed.

| Factor | Considerations for Choosing the Ideal Pipe Stand |

|---|---|

| O/D Pipe Diameter | Pipe stands must match pipes’ outer diameter for safety and stability. |

| Material | Stand and pipe materials must be compatible to avoid corrosion. |

| Total Weight | Pipe, contents, attachments, and relevant work equipment must be accounted for. Overloading can lead to instability and injury. |

| Total Length | Longer pipes need more pipe stands to prevent sagging and misalignment. |

| Wall Thickness | Thicker pipe walls increase overall weight and require additional support strength. |

| Task to be Performed | Stand features should suit specific operations like welding or cutting. |

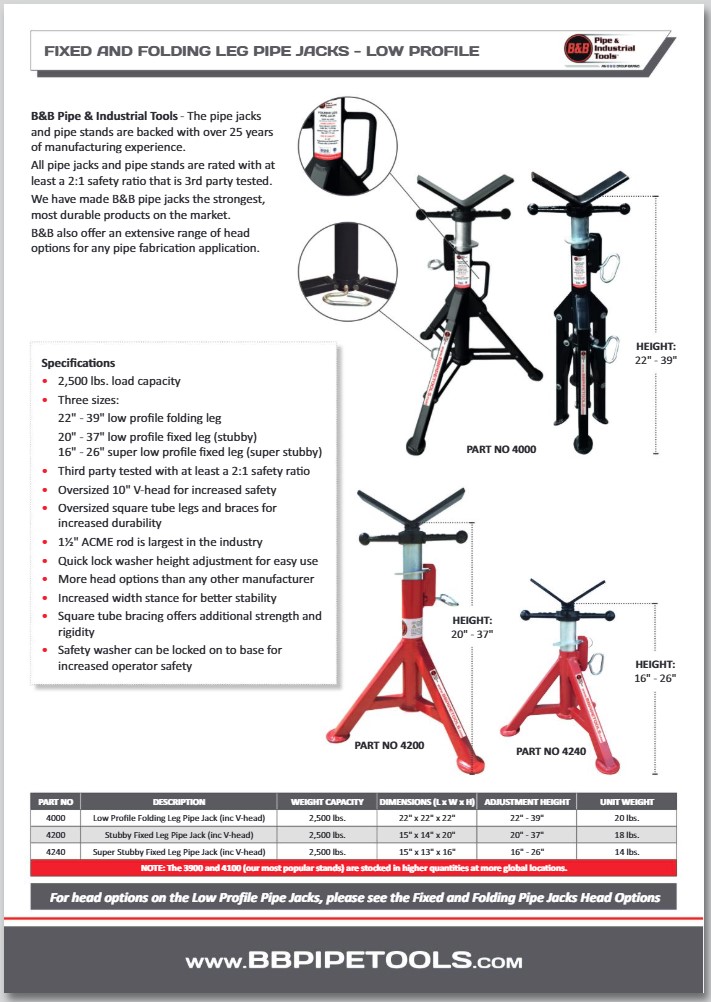

Factor #1: O/D Pipe Diameter

The outer diameter (O/D) of the pipe is one important consideration not to be missed when selecting a pipe stand. Diameter measurements can be tricky, as product brochures or data sheets are often unclear as to which pipe diameter they reference.

Source: AllAboutPiping.com

Tips:

- Match Stand Capacity: Confirm that the specifications of the pipe stand match the O/D of the pipe. For example, pipes with 50-inch O/Ds should not be mounted on stands capable of accommodating diameters ranging 2 to 48 inches.

- Use V-Head Stands: V-head stands give great stability for round pipes since they cradle the pipe and control rolling motion.

- Consider Adjustable Stands: You may be working at a site that deals with multiple pipe sizes. Adjustable stands are versatile and can be suited to various diameters.

It can be tough to choose from the many companies that provide very adaptable stands. Check out the B&B Duo pipe stand to save you time. Besides being height adjustable, this piece of equipment works with pipe sizes spanning 2 to 48 inches.

Choosing a stand appropriate for the pipe’s size improves safety and lowers the risk of expenses related to damage during operations.

Factor #2: Material

Although pipe stands are usually constructed of sturdy materials, this doesn’t mean they are bulletproof.

Since pipes and supports are in contact with each other, their materials have to be compatible for optimal safety and performance. Otherwise, system integrity will be compromised and worker well-being put at risk.

Tips:

- Ensure Material Compatibility: Steer clear of putting stainless steel pipes on galvanised steel supports since this might lead to corrosion as time goes by.

- Choose Appropriate Stand Material: Steel stands are strong and durable enough for heavy-duty uses. Meanwhile, aluminium stands offer lightweight portability for less demanding applications.

- Consider Environmental Conditions: Corrosive environments like the coast or the sea need pipe stands coated with anti-rust materials. Otherwise, these support structures won’t last long.

Factor #3: Total Weight

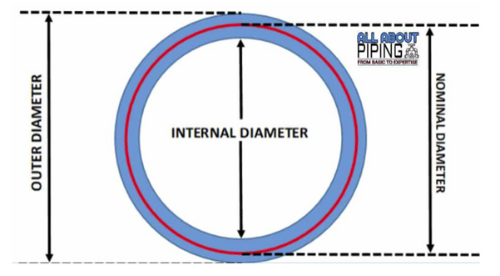

When speaking with a pipe stand dealer or manufacturer, clarify the load capacity you see on their brochures or datasheets. Is the indicated load capacity of their pipe stand based on the weight of the pipe alone or the total weight in the system?

The load the stand must be able to bear must account for the total weight of the pipe, its contents, and any attached working instruments. Injuries and instability may result from either exceeding the capacity of the stand or ignorance of exact load numbers.

Tips:

- Calculate Total Load: When calculating the required load capacity of your pipe stand, add the weight of the pipe, its insulation, fluid, valves, cutting or welding tools, and other attachments.

- Select Appropriate Load Capacity: Choose stands rated for the total calculated weight. For instance, our brochure for our B&B 3-Leg Giant Jack shows that our product can withstand a total load of 5,000 lbs (2,268 kg) without roller wheels. If you need to use our product’s roller wheels to perform complex tasks like pipe cutting, your pipe and its related attachments must not exceed 2,500 lbs.

Factor #4: Pipe Length

Imagine holding a pole vault pole horizontally, using your hands as support. The very long stick will sag as you hold it.

The same thing happens with long pipes on poorly placed and inadequately few pipe stands. Whether you are welding or cutting, you need the right amount and spacing of pipe stands to maintain alignment and prevent undue stress.

Tips:

- Use Multiple Stands: For extended pipe lengths, use multiple stands to distribute weight evenly and maintain stability.

- Adjust Stand Spacing: Position stands at intervals that prevent pipe sagging and support the pipe adequately throughout its length. A safe rule of thumb is that for every 5 feet (1.5 metres) of pipe, there should be at least one pipe stand.

- Consider Stand Mobility: For tasks requiring pipe movement, such as rolling or rotation, use stands with rollers to make handling easier for your workers and prevent any pipe damage. It is difficult to rotate extremely long pipes and keep them in one piece if you do not have adequately designed and properly placed pipe stands.

Factor #5: Wall Thickness

Even if your pipe is built of light alloys, carefully monitor the load capacity of your stand as well as the weight and wall thickness of your pipe. Notwithstanding its material composition, a pipe’s wall thickness adds to its total weight. Choose the best pipe support for your worksite with this in mind.

Tips:

- Account for Increased Weight: Make sure that your thick-walled pipe’s weight matches the load capacity of its stand.

- Ensure Proper Support: Use stands that provide adequate support to prevent deformation or damage to your thick-walled pipe during operations.

- Verify Stand-Design Compatibility: Ensure that the stand’s design matches your pipe’s wall thickness to maintain stability and safety.

Factor #6: Task to Be Performed on the Pipe Stand

The features required in your stand depends on what you will do with your pipe. Tasks such as cutting, welding, surface treatment, demolition, or repair require different pipe stand designs and configurations.

Tips:

- Cutting: Use stands with rollers to allow smooth rotation of your pipe and help you make accurate cuts.

- Surface Treatment: Select stands that provide unobstructed access to your pipe’s various surfaces, enabling thorough treatment or inspection.

- Demolition or Repair: Employ heavy-duty stands when removing or maintaining your pipes to ensure safety and efficiency at your worksite.

- Welding: Opt for stands that offer stability and precise alignment to ensure clean welds. V-head or adjustable-height stands are beneficial.

Aside from flexibility in terms of height adjustments, welder pipe stands should accommodate various types of equipment typically required on site. A pipe holder that best exemplifies this is the B&B Tri-stand Chain Vice. This pipe stand’s leg bracing doubles as a lipped shelf for holding additional tools and devices.

You’ve just learned about the many factors that come into play when choosing the ideal pipe support for your project. Armed with this information, you are now ready to approach your chosen pipe stand manufacturer.

But before visiting a dealer, it is worthwhile to browse the next section of this article.

Things to Consider When Selecting Pipe Stand Manufacturers

Ultimately, you want to ensure safety and convenience not only during your operations but also long after the purchase of your pipe stand. That is why when visiting a stand dealer or manufacturer, watch out for or ask about the following to ensure you get the best deal:

- CE Marking: Confirms compliance with the European Union’s safety rules for pressure-related devices. Choosing CE-marked stands assures you that they meet fundamental health, safety, and environmental criteria under EU law.

- Loading Certificates: Demonstrates that each stand has been certified to carry certain pipe loads or weights. If a load-test certificate is missing, you should arrange for independent testing to ensure your pipe stand can withstand its intended workload.

- Considering Additional Equipment in Load Capacity: Ensures that add-ons (e.g., rollers, chocks, adapters) are factored into your stand’s safe working load. Overlooking accessory weight can overload your pipe stand and damage it without warning. Consult the manufacturer’s datasheet or speak with the sales representative present for accessory weights and recommended loading combinations.

- Warranty and After-Sales Support: Provides peace of mind through guarantees and manufacturer backing. Search for businesses providing warranties covering at least one year for flaws in materials and workmanship. Top suppliers will also provide continuous after-sales assistance and guarantee spare part availability.

Pipe Stands Built to Stand the Test of Time

To summarise, when selecting the right pipe stand for your project, it is important to consider the following:

- The goals of your project

- The characteristics of the pipe to be supported

- The environment in which you will be working

- The physical characteristics of the pipe stand you will use

- The quality of the pipe stand’s manufacturer or dealer

By understanding these, you can choose a reliable and high-performance pipe holder that improves the safety and efficiency of your projects.

For decades, the SFE Group has upheld standards of reliability, safety, and efficiency in various worksites across the globe. From the 90-year-old pipe fitting company Mathy Dearman to the 30-year-old construction equipment manufacturer B&B, our multinational brand has provided time-tested support for pipes and robust tools for contractors of all shapes and sizes.

Contact us today and let’s build lasting legacies together.