The rejected stone has become the cornerstone.

These words from a wise carpenter symbolise our tendency to ignore the ordinary things that are actually vital. Consider the humble pipe stand. Is it just a holder of pipes during welding? Or is it a vital component of worksite safety?

Professionally built pipe stands offer welders protection that ordinary tables or platforms cannot. Welder safety can yield dividends that go beyond physical protection. With increased safety, efficiency, productivity, and cost savings are not far behind.

Read this article to gain fresh insights into what pipe stands are, why they are crucial in fostering safe welding operations, and what to consider when selecting and using pipe stands to enhance welder safety.

What Exactly is a Pipe Stand?

A pipe stand is a special type of platform designed to securely hold and support pipes during welding, cutting, fabrication, repair, or transport. Regardless of the application, the pipe stand’s primary function is to provide a stable surface, ensuring that heavy and unwieldy pipes remain steady throughout the work process.

More than merely being a workbench for pipe welding projects, pipe stands are crucial tools for welding safety. The next section further elaborates on this point.

Why Are Pipe Stands Vital for Safe Welding Operations?

Pipe stands enhance welder safety by:

- Minimising rework: Every additional second a worker spends welding increases their exposure to potential accidents. Choosing the ideal pipe stand for your particular project can enable your welders to perform intricate tasks correctly the first time, reducing the possibility of mishaps while saving time.

- Reducing manual handling risks: The less welders need to use their own physical power to adjust heavy pipes, the less likely they will sustain strain injuries and suffer accidents.

- Providing ergonomic benefits: By holding pipes securely at the optimal height and angle, pipe stands help welders maintain proper posture. Given that sustained bad posture can lead to musculoskeletal disorders, pipe stands minimise the risk of long-term medical problems.

It is clear that robustly designed and constructed pipe stands foster welder safety. But not all welding jobs are alike.

To help you choose the safest pipe stand for welding, the next section will discuss the factors you need to account for and some useful tips for using pipe stands.

5 Factors to Consider When Selecting Welding Pipe Stands

When choosing a pipe stand for welding, it is important to balance safety, stability, and ease of use.

The table below summarises key factors to consider when selecting the most appropriate pipe stand for your welding tasks. An in-depth discussion of the table’s contents and related tips on pipe-stand usage follows.

| Factor | Why It Matters |

|---|---|

| O/D Pipe Diameter | Determines the optimal spacing of pipe stand rollers, which affects pipe stability and rotation during welding. |

| Stand Material | Affects the balance between strength, portability, and heat/spark resistance. |

| Total Pipe Weight | Impacts pipe stability during welding. |

| Total Pipe Length | Determines whether a pipe tips or undergoes mid-span deflection. |

| Pipe-Wall Thickness | Influences pipe stiffness and susceptibility to deformation. |

Factor #1: O/D Pipe Diameter

Why it matters:

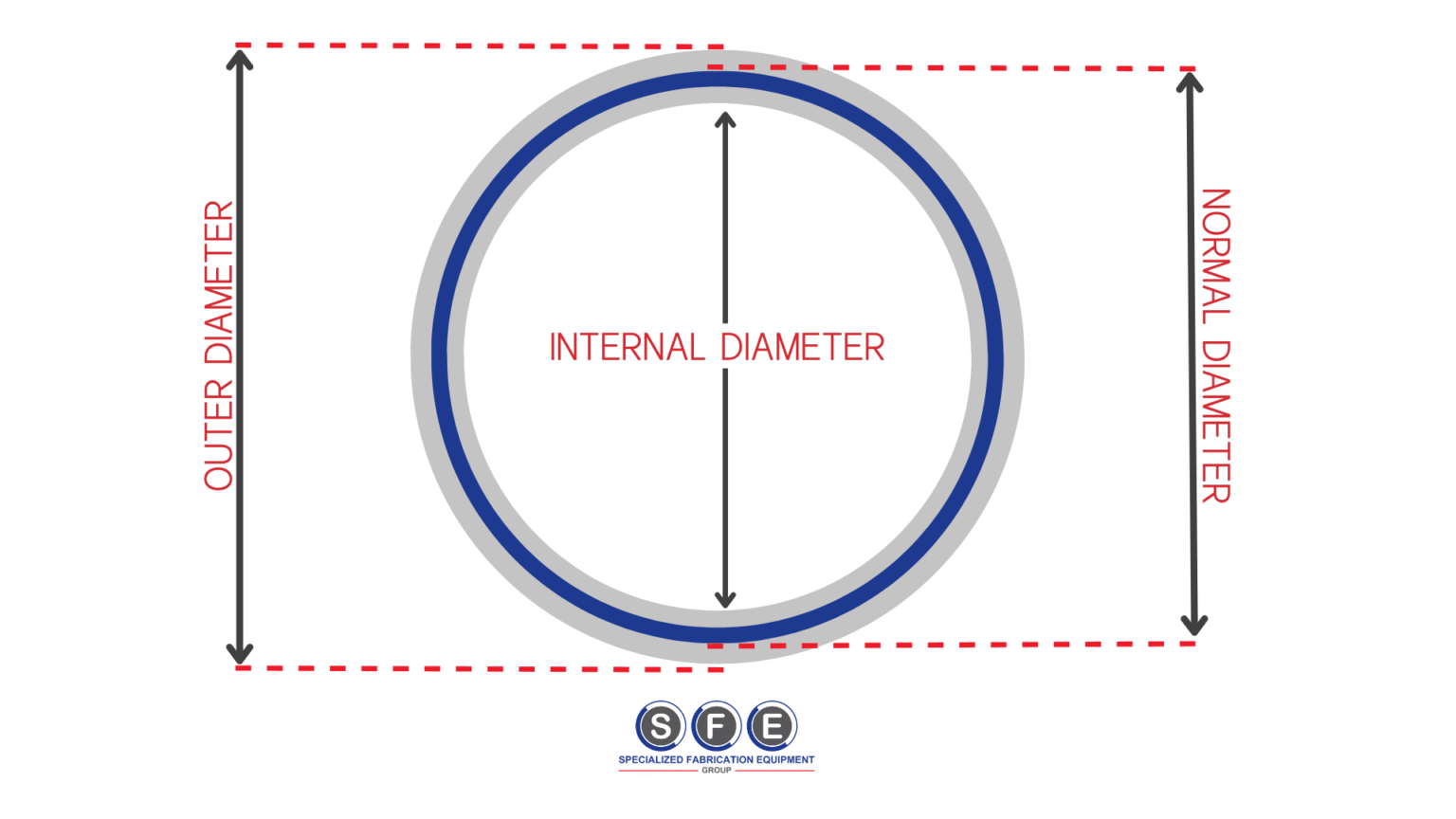

The outer diameter (O/D) of the pipe is an important factor to consider when choosing a pipe stand for welding. Diameter measurements can be confusing, as product brochures or data sheets are often unclear as to which pipe diameter they reference.

When buying a pipe stand for welding, make sure you know the outer diameter of your pipe and purchase accordingly. If you have no idea how to measure your pipe’s O/D, the video below provides quick and useful advice.

So, why is a pipe’s O/D important when choosing pipe stands for welding?

Knowing your pipe’s outside diameter can help you better select the proper type of pipe support equipment. Among the various types of pipe holders available, pipe roller stands are ideal for welding operations.

So, why is a pipe’s O/D important when choosing pipe stands for welding?

Knowing your pipe’s outside diameter can help you better select the proper type of pipe support equipment. Among the various types of pipe holders available, pipe roller stands are ideal for welding operations.

These pipe support systems are designed with rollers on top, enabling easy pipe rotation. These pipe roller stands enable workers to weld more easily and evenly around the circumference of the pipe, without exerting too much physical effort.

Roller stands are topped with wheel-like components called rollers (see image below).

The outside diameter of the pipe determines the ideal gap between the two rollers of your chosen pipe stand. If your stand’s rollers are spaced too close to each other, they will pinch the pipe you are trying to weld, impeding rotation. If the rollers are too far apart, the pipe will wobble, risking misalignment or a poor-quality weld.

Tips for pipe-stand selection and usage:

- Measure Your Entire Pipe Range: If you’re working with pipes of different diameters, take stock of all pipe sizes in use. Measure the O/D of your smallest pipe and largest pipe and choose a pipe stand whose adjustable rollers can accommodate both diameters.

- Ensure Even Support: When welding large-diameter sections, use at least two stands spaced appropriately to prevent sagging.

When working with large and heavy pipes, stands with V-heads complement pipe roller stands well. Though V-head stands do not allow for pipe rotation, they tend to be more stable. Whenever the number of pipes that need servicing exceeds the number of welders, you can use V-head stands to safely hold or transport pipes awaiting welding.

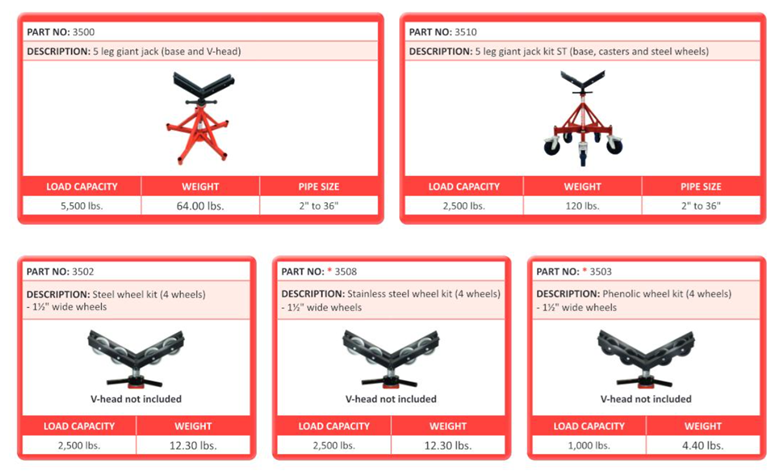

For optimal cost-effectiveness in high-volume welding environments, pipe stands with interchangeable rollers and V-heads are ideal. One such pipe stand is B&B’s 5-Leg Giant Jack, which can be fitted with V-heads or roller wheels, depending on your worksite requirements.

If you have more questions about our 5-Leg Giant Jack, contact us today to maximise safety, stability, and efficiency in your welding sites.

Factor #2: Stand Material

Why it matters:

To promote welder safety, strength and durability are not the only characteristics that pipe stands need to possess. Pipe-stand materials must also resist sparks and heat to reduce the likelihood of costly and harmful fires.

The following pipe stand materials combine spark resistance with other qualities that make them valuable in different welding environments:

- Steel – Extremely durable and cost-effective, but heavier to move; ideal for welding heavy pipes in areas permanently designated for the purpose.

- Aluminium – Lightweight, non-flammable, and corrosion-resistant; ideal for frequently relocated setups, though typically lower load capacity.

- Composite/polymer – Non-conductive and spark-resistant, suited for electrically sensitive environments but can carry relatively lighter pipes.

Tips for pipe-stand selection and usage:

- Match Stand Material to Environment: Use steel stands in heavy-duty shop settings, aluminium when portability is paramount, and composite materials if electrical insulation is absolutely necessary.

- Verify Load Ratings: Aluminium or composite stands often carry relatively lighter pipes while steel can handle heavier loads. Make sure that your stand’s safe working load (SWL) exceeds your pipe’s total weight (including pipe content, equipment attachments, and any additional fittings).

Factor #3: Total Pipe Weight

Why it matters:

If a pipe and its contents or fittings are too heavy for your stand, then your pipe support system will collapse, leading to substandard welds. The collapse can also lead to injuries, especially if the welder is not wearing heavy-duty construction boots.

To ensure safety and efficiency on the welding site, it’s crucial to determine your pipe’s total weight and make sure it is less than or the same as your stand’s safe working load rating.

When measuring the pipe’s total weight, take into account the weight of the pipe itself, along with any of the pipe’s content or attached tools. It is also crucial to keep in mind that diameter, wall thickness, and length also affect total pipe weight.

Tips for pipe-stand selection and usage:

- Check the Stand’s Rating: Look for “Safe Working Load” (SWL) on the specification sheet of your pipe stand. Make sure that number is higher than the total weight the stand will carry. For example, if your stand has an SWL rating of 331 lbs (150 kg), your pipe and any attachments must not weigh beyond this limit.

- Spread the Load: Use more stands under a heavy or long pipe. For instance, three stands under a 15-ft (4.5-m) long, 661-lb (300-kg) pipe means each stand supports about 220 lbs (100 kg)—evenly distributing an otherwise heavy load.

- Account for Extra Equipment: If you’re adding chucks, rotators, clamps or heavy welding fixtures, add their weight into your total load and make sure the figure is less than or equal to the pipe stand’s SWL.

Factor #4: Total Pipe Length

Why it matters:

Welds must be executed with utmost quality and consistency. For longer pipes that are not supported well, doing so is more difficult because excessive pipe length introduces leverage and bending forces.

Pipe stands must resist tipping and provide consistent support along the span to ensure successful and injury-free welds.

Tips for pipe-stand selection and usage:

- Use Multiple Stands at Proper Intervals: A safe rule of thumb is that for every 5 feet (1.5 metres) of pipe, there should be at least one pipe stand.

- Consider Height Adjustability: Flexibility of pipe-stand height allows for a more fine-tuned alignment across multiple support points, ensuring a straight, level welding plane.

- Choose Stands with Wide Bases: Wider footplates or tripod designs offer greater lateral stability for long pipes.

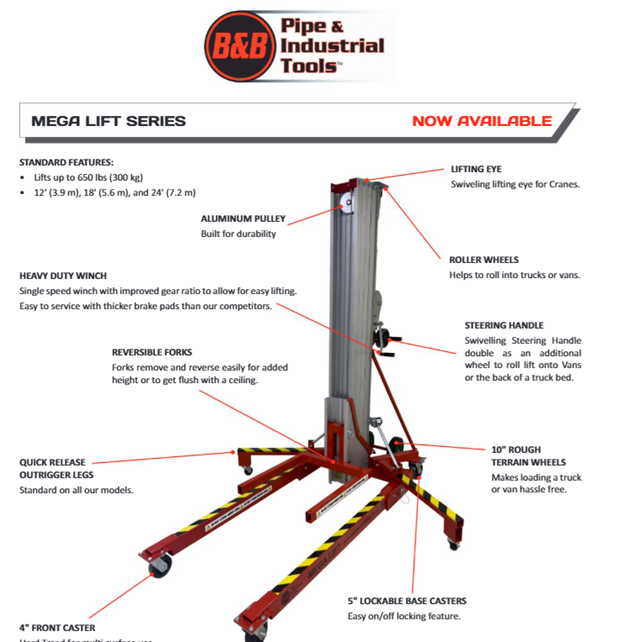

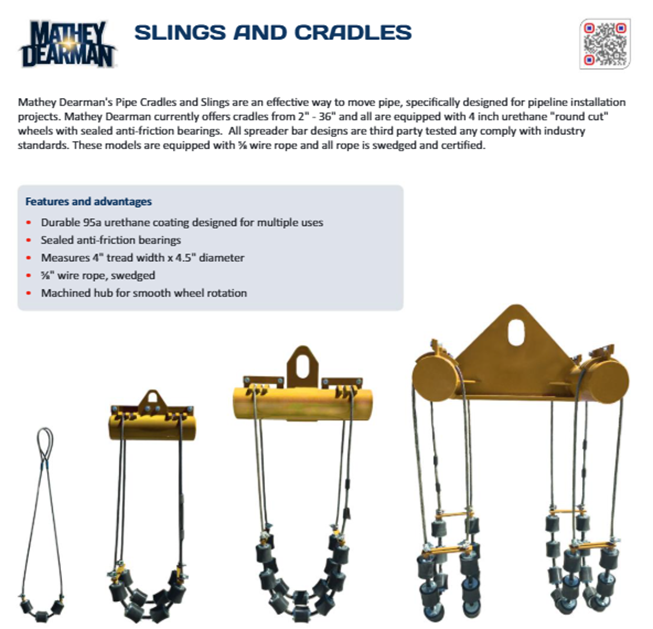

As long pipes are often heavy, it’s important to use equipment that minimises strain or injury when lifting or moving them. You may use pipe rigging equipment such as B&B’s pipe lifts or Mathey Dearman’s pipe slings and cradles for this purpose.

Factor #5: Pipe-Wall Thickness

Why it matters:

The thickness of your pipe’s walls affects the way the pipe moves on your roller stand while welding. Any irregularity of movement during pipe rotation can produce inconsistent and low-quality welds.

Thicker-walled pipes are heavier and stiffer, affecting how the stand grips and rotates the pipe. By contrast, pipes with thin walls may deform if your stand’s rollers are too closely spaced to each other.

Tips for pipe-stand selection and usage:

- Carefully Adjust Rollers for Thin Walls: Make sure the space between your stand’s rollers is not too tight to prevent denting or deforming thin-walled pipes.

- Ensure a Firm Grip on Thick Walls: For heavy-walled pipes, your stand should have high-friction rollers to prevent slippage.

From Safety Assets to Success Partners

Pipe stands are crucial tools for enhancing safety in your welding operations. The extent to which your pipe stand fosters safety depends mainly on its design and compatibility with the pipe being welded.

As you may already know, welding is just one of the many crucial jobs performed on pipes. Whether you are building vital infrastructure or constructing vehicles that support global economies, chances are, you also need to cut, shape, and transport pipes.

At SFE Group, we offer a whole suite of products and services for various pipe-fitting needs. We manufacture and distribute clamps, rigging, and tools for beveling and cutting pipes. With our brands’ century-long experience serving global contractors, you can rely on us to be your co-builders of a brighter future.

Turn your pipe work into long-lasting legacies. Contact us, and let’s outline a clear plan for your project’s long-term success.